Single Diameter and Dual Diameter Rolling Jigs - Dual diameter jig includes ~.012" indent to ease the rolling process. NOTE: Single Diameter/regular jig works for both but DD rolling jig makes it a little easier.

Templates and guides to help create precise and consistent paper patches.

Adjustable length paper patch cutting template - adjust to any length for any bullet between .30 and .50 calibers - Includes extensions for .Dual Diameter and .50 cal

Extra thick - to help guide the cutting knife

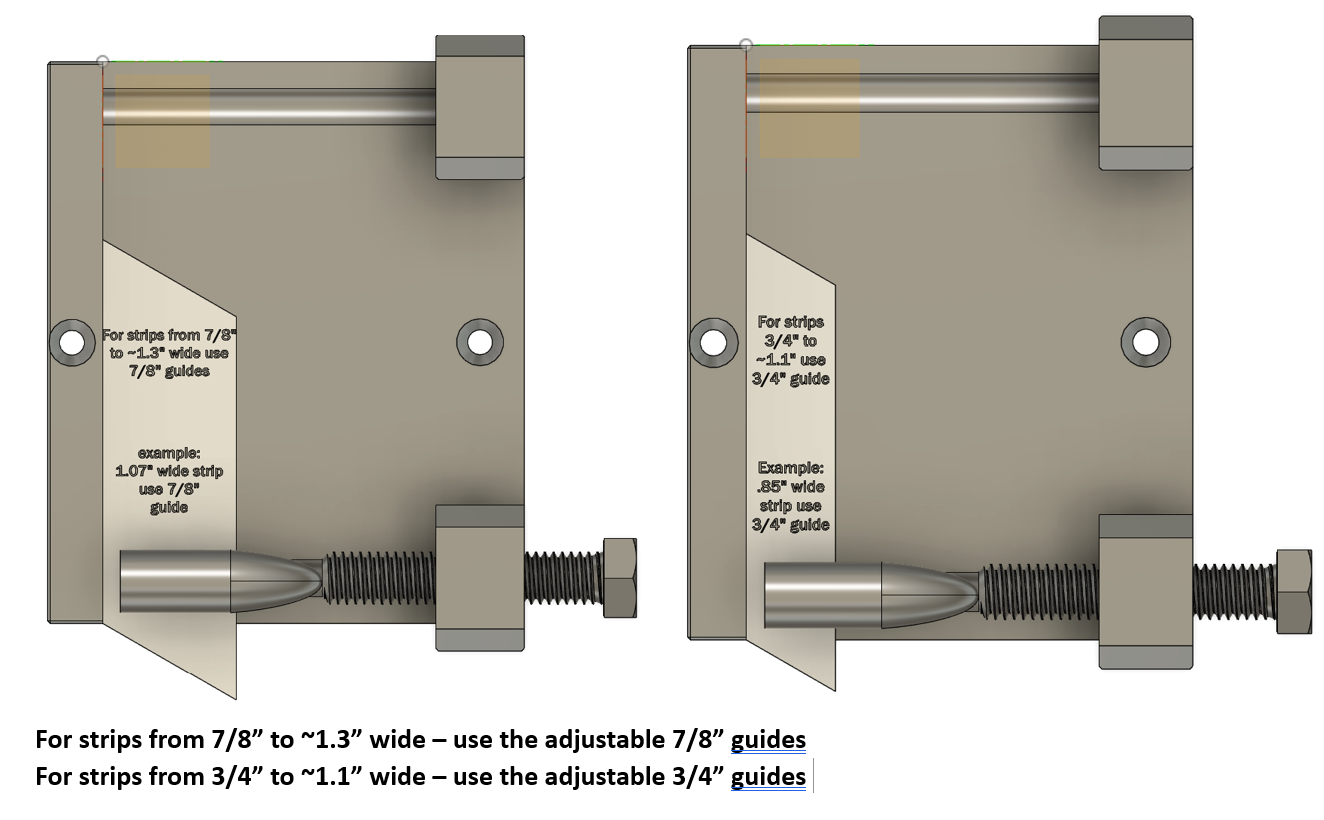

Paper strip cutting guides are width adjustable with threaded spacers.

- Strip cutting guides have a built in arch. This forces the downward pressure applied in the center of guide to be transferred to the ends, providing constant pressure across the entire length. This helps not only to keep the guide from shifting while cutting, but also helps prevent the knife from gathering the paper on the end when starting the cut. The guide has a slot to fit an Exacto style knife to help keep it at a constant angle throughout the cut.

- Cutting guides available in 7/8" wide (adj to 1.3") AND 3/4" wide (adj to 1.1"). 7/8" wide are preferrable and easier to manage when cutting but 3/4" may be necessary when cutting the narrower patch to use with shorter bullets (See cutting guides sizing picture for reference)

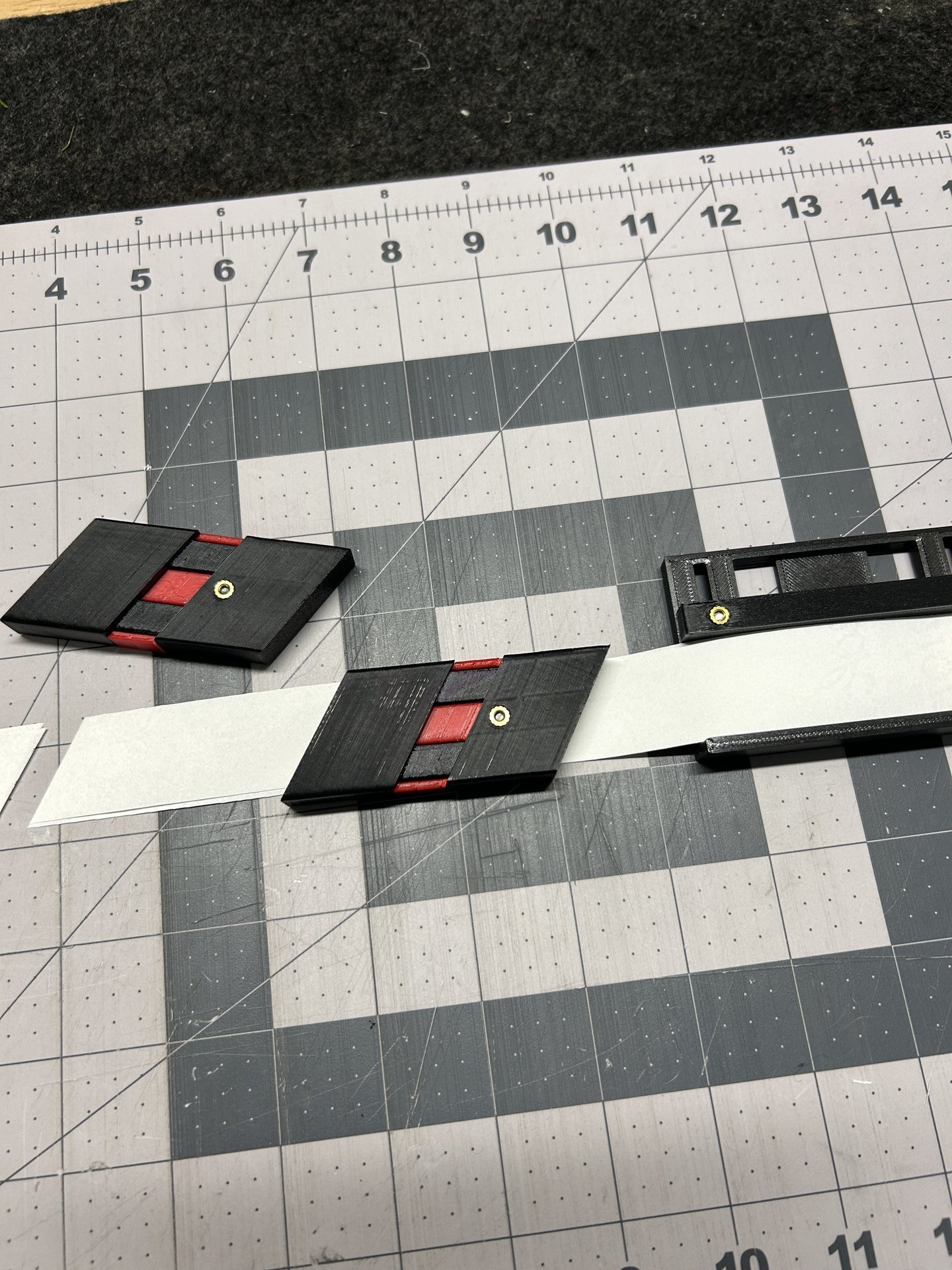

Paper strip alignment jig helps keep multiple strips in alignment while cutting final patches with the patch cutting templates. (Especially useful with Seth Cole 55W paper or other light tracing papers)

Demonstration of how to use all the paper patch tools

Cutting Strips for patches

Cutting the patches

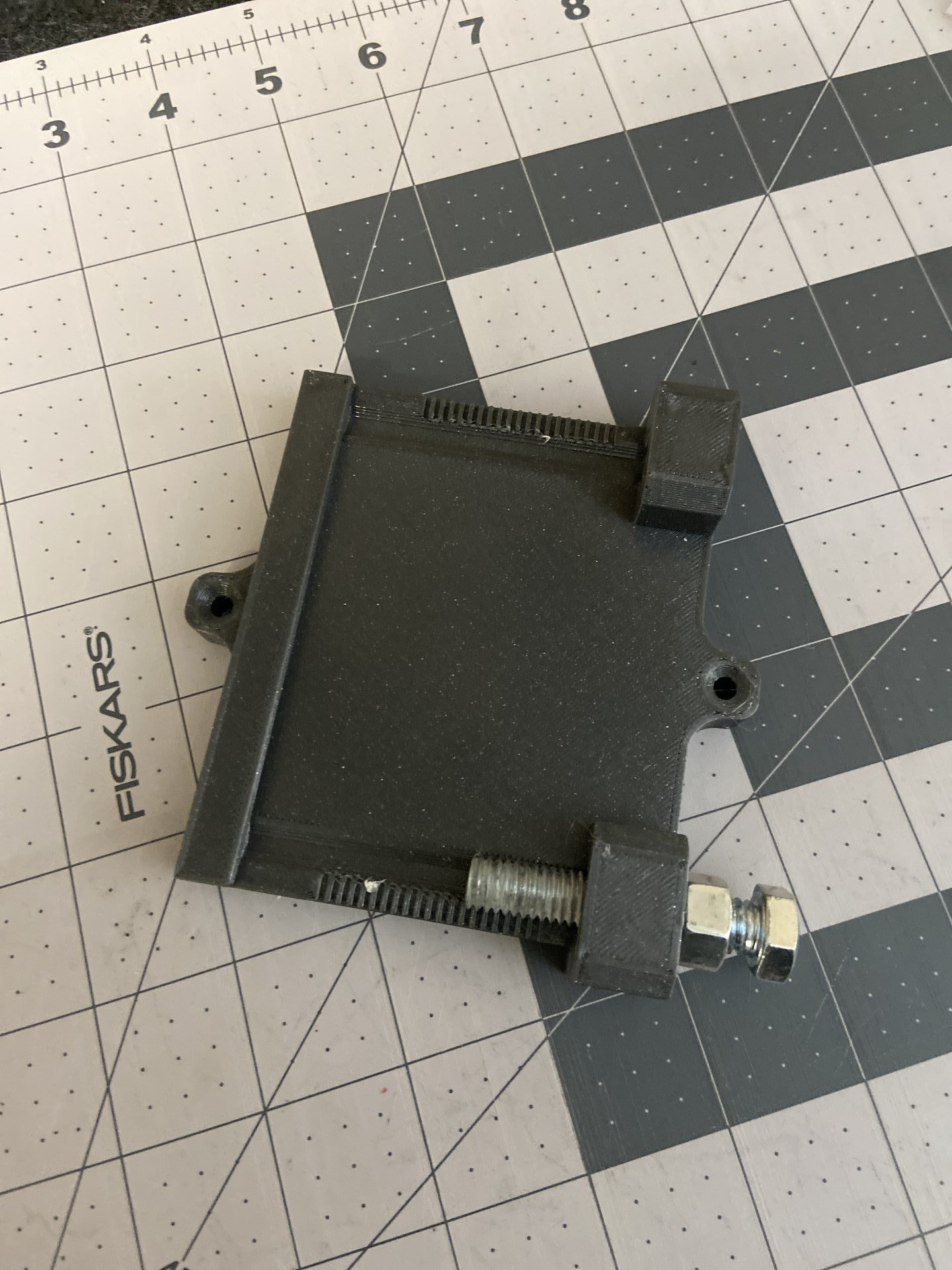

Paper Patch Rolling Jig

- Keep paper aligned perfectly perpendicular to the bullet

- Easily adjust exact distance of the paper from the nose of the bullet

- Stabilize the bullet before starting the wrapping of the paper

- Mounting holes to attach to larger board if desired

- Move adjuster bolt to opposite holder and turn jig around to position paper on the right side with the adjuster bolt on the left

Wet patching demo: (should work fine for dry patchers as well)